Medical equipment is exceedingly delicate. Surgical instruments must meet strict requirements to function efficiently and must withstand a variety of stressors. In medical contexts, chemical reactions pose a considerable concern because reactive materials can contaminate crucial medications or testing procedures, as a result, medical device items must be designed from the start with the ultimate objective in mind, taking into consideration structural design elements as well as resource selection techniques to create the best component for each case.

Medical-grade plastics are fast becoming the medium of choice for a diverse variety of surgical instruments. The superior mechanical qualities of healthcare molding polymers allow for the total elimination of metals from operational instrument designs. In other cases, metal and plastic elements can be combined to make a better item with features that would be impossible to achieve with either an all-metal or all-plastic technology.

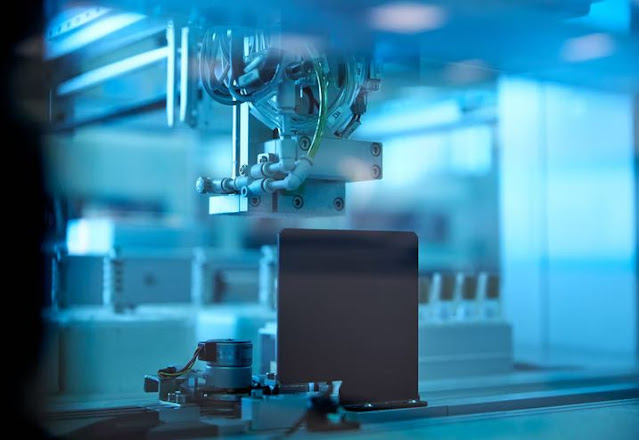

Injection molding allows device manufacturers to create complicated parts with high part-to-part consistency, but selecting the apt material and method is crucial. The cost-effective medical plastic injection molding technology is excellent for massive production operations and applications that need uniformity and strict standards; molding procedure in the fabrication of medical equipment prototypes for FDA approval and test procedures.

Material Usage

Durable plastic materials with high molecular mass and chemical and thermal resistance are used in the medical injection molding process. Polycarbonate is a pharmaceutical-grade plastic that is inherently clear and often used for surgical equipment. It has good tension, shearing, and modulus of elasticity. It's also more heat resistant, has a lower humidity absorption rate, and is more durable than acrylics.

PEEK is a rare genetic plastic material that is chemically robust, resistant to breaking and strain, and can be autoclave sterilized. It has a UL 94 V-0 combustibility certification and is FDA approved for contact with food. Ultem is another material that is used in medical equipment and can be sterilized in an autoclave. It is hard and brittle and chronic conditions, has great structural accuracy, and is rigid.

Let us look at some top benefits of Injection Molded Surgical Devices

1. Cost Quotient

Injection molding is one of the most cost-effective manufacturing technologies today, notably when producing large quantities. Plastic injection mold is virtually usually the most cost-effective solution when healthcare supplies, equipment, and gadgets are needed in large quantities.

Due to the sheer cheaper price-per-part, large manufacturing quantities tend to repay manufacturing costs over time. As a result, injection molding is ideal for equipment such as tanks, pipes, and single-use hospital instruments such as syringes. All of your healthcare industry demands may be met by using injection molding.

2. Weight Quotient

Mechanical characteristics of modern treatment polymers, especially filled polymeric materials, are comparable to those of traditional metals. Polymer resins are a direct replacement for metals in several instances, giving the equivalent performance of the device while drastically decreasing equipment mass. Reduced weights can assist surgeons to work more efficiently in the surgical procedure by reducing tiredness during protracted operations.

3. Durability Quotient

Many injection-molded plastics are sturdy and durable, withstanding severe conditions, vibrations, and pressure without snapping, fracturing, or exploding. Many injection molding plastics are also resistant to heat, allowing them to be disinfected regularly using an autoclave or other methods.

Tight-tolerance manufacturing is crucial in the medical sector, where millimeters or microns may make or break a product's effectiveness. Appliance injection molding factories with advanced technology can create large numbers of systems and sensors with excellent precision and minimal variation from unit to piece.

4. Versatility Quotient

Several synthetic plastics are readily accessible on a commercial scale and can be used in production. Fortunately, many of these polymers may be used in medical equipment. These plastics have well-understood physical and thermal characteristics, making it simple to select the one that is best suited to the final application and atmosphere. Thermostable, chemical resistant, robust, inexpensive, biodegradable, and nontoxic resins are available.

When it comes to prostheses, replacement joints, and other diagnostic implants that will be in constant touch with the person, plastics are becoming incredibly common. You can discover the perfect match for your healthcare gadget among the many plastics accessible for the injection molding process.

5. Functionality Quotient

Coating surgical equipment is impractical, and colorization is limited to the simple metal color. Injection molding makes for easy coloring inside the plastic, as well as organic clarity in some cases. It brings some path-breaking opportunities: surgical tools and gadgets can be the color scheme for simple recognition, or doctors can see through transparent plastics for better sight during surgeries.

Medical devices injection moulding plastics are designed to be foreign - body resistant and easy to sterilise. Furthermore, the injection molding technique is simple to comply with FDA and other regulations.

6. MRI Compatibility

Most metals can not be used in large magnetic fields, such as those encountered in MRI situations, due to their magnetic characteristics; plastics are impervious to the electromagnetic field, therefore, injection-molded equipment is safe when it is used near or beside MRI scanners.

Overmolding is the process of molding a polymeric covering over a section of metals to transmit specialized characteristics, such as increased handle and controls while keeping the underlying metal tool's toughness and energy absorption. Alternatively, since certain elements are pricey out of metals, plastic can be utilized to substitute a sophisticated section of a gadget.

Final Words On Injection Molding For Surgical Devices

The way things are progressing in both technical and medical domains, the surgical devices and equipment are upgrading at such rapid speed that the future is bright for both the surgeons and the patients. The advancement in technology has already made operations precise. With such improvements, the process has given confidence to surgeons to take bold steps and save more lives than before.

It is why plastic injection molding is so well-suited to medical equipment fabrication: the molding process is reliable and systematic, ensuring a stable quality month by month, season after season, and the ability to produce massive volumes of identical components.