Modern business owners are constantly looking for cost-effective solutions to develop new products. With business owners like yourself constantly attempting to save money, you need to find a production solution offered at a fair value. With the best design solution in place, you can quickly begin developing prototypes or producing inventory.

Before you select a production method, it is often beneficial to overview all manufacturing and design options available. There are multiple methods available whether you are looking to reduce production costs, change manufacturing tactics, or get a prototype made. Read on to learn about the top cost-effective ways to design new products.

Consider Traditional Manufacturing Procedures

As you plan cost effective manufacturing processes, it often helps to first consider traditional methods. The most common form of traditional manufacturing is assembly line, or repetitive production. With appropriate access to equipment and resources, these traditional manufacturing options can design any product to your exact specifications. By using your existing manufacturing, you can save money for your business while developing new products. In addition to repetitive options, you can additionally produce your goods using a discrete manufacturing process. These traditional production processes are often incredibly cost-effective as long as you are manufacturing goods in bulk. In order to design and produce new products, consider traditional manufacturing options.

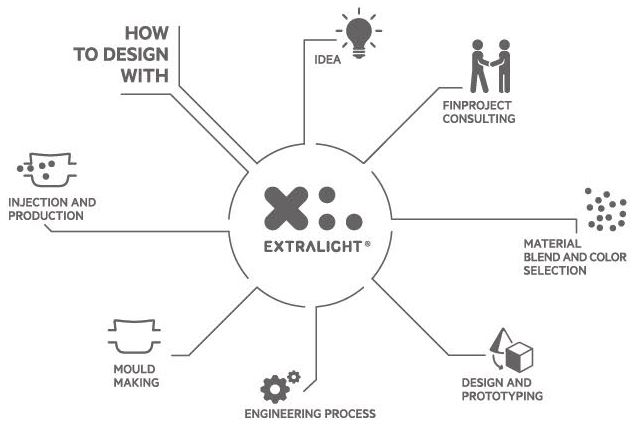

Assess Foam Injection Molding Opportunities

Foam injection molding is another way to develop and design new products for entrepreneurs on a budget. This type of injection molding is a cost effective strategy to develop lightweight, durable, and aesthetically pleasing products. The foam injection molding process is conducted by melting thermoplastic materials and applying a blowing agent to create a foamy substance. Then, this foamy substance can then be injected directly into custom molds based on your product depiction.

Consider Traditional Manufacturing Procedures

As you plan cost effective manufacturing processes, it often helps to first consider traditional methods. The most common form of traditional manufacturing is assembly line, or repetitive production. With appropriate access to equipment and resources, these traditional manufacturing options can design any product to your exact specifications. By using your existing manufacturing, you can save money for your business while developing new products. In addition to repetitive options, you can additionally produce your goods using a discrete manufacturing process. These traditional production processes are often incredibly cost-effective as long as you are manufacturing goods in bulk. In order to design and produce new products, consider traditional manufacturing options.

Assess Foam Injection Molding Opportunities

Foam injection molding is another way to develop and design new products for entrepreneurs on a budget. This type of injection molding is a cost effective strategy to develop lightweight, durable, and aesthetically pleasing products. The foam injection molding process is conducted by melting thermoplastic materials and applying a blowing agent to create a foamy substance. Then, this foamy substance can then be injected directly into custom molds based on your product depiction.

These custom molds allow you enhanced flexibility over the design, size, and shape of your final product. If you are interested in the top cost-effective ways to design new products, consider foam injection molding.

Research Custom Production Services

Businesses looking for unique, cost-effective manufacturing methods should consider opportunities in custom production. Custom production services individually produce specific goods to meet client needs. Custom production specialists can specialize in specific industries, or work universally to develop client products. Commonly, these are service providers like contractors, sourcing agencies, artisans, or craftspeople. As individual services, the cost for custom production services frequently vary. However, many specialists work directly to meet their clients' design and price requirements. Because of this, custom production can actually be one of the most cost effective methods to produce your products.

3D Printing

One of the quickest growing manufacturing methods for cost conscious entrepreneurs is 3D Printing. 3D Printing is one of the quickest, most inexpensive methods to design and manufacture new products. Commercial printing technology uses software to design a three-dimensional computer-aided model. Printing technology is becoming increasingly accessible, reduces your production waste, and is more sustainable than traditional, fuel-consuming equipment. This has allowed many entrepreneurs like yourself increased flexibility over the design and production of their products. If you are looking for the top cost-effective strategies to manufacture new goods, consider 3D printing technology.

Build It Yourself (DIY)

When it comes to designing your products, there is no cheaper method than doing it yourself. If your product concept is relatively easy to design and assemble, consider attempting to build it yourself. Make a list of all the supplies you need to build your product. Check with your local hardware store to see what type of equipment they carry. Not only does self-assembly save you money, it better familiarizes you with the functions of your designed product. When you build products yourself, you can utilize savings to test market new products. If you have previous knowledge and expertise in how your product should work, consider purchasing the equipment to build it yourself.

Conclusion

Entrepreneurs are constantly looking for the best cost-effective methods to build their planned product designs. The first step is to consider the traditional manufacturing methods. Assess opportunities foam injection molding your product prototype. Consider custom production options with local businesses and experts in your area. If you have access to the technology, consider 3D printing your product designs. Furthermore, in order to save additional money throughout your manufacturing process, consider building it yourself. Consider the points above if you are interested in the top cost-effective ways to design new products.

Research Custom Production Services

Businesses looking for unique, cost-effective manufacturing methods should consider opportunities in custom production. Custom production services individually produce specific goods to meet client needs. Custom production specialists can specialize in specific industries, or work universally to develop client products. Commonly, these are service providers like contractors, sourcing agencies, artisans, or craftspeople. As individual services, the cost for custom production services frequently vary. However, many specialists work directly to meet their clients' design and price requirements. Because of this, custom production can actually be one of the most cost effective methods to produce your products.

3D Printing

One of the quickest growing manufacturing methods for cost conscious entrepreneurs is 3D Printing. 3D Printing is one of the quickest, most inexpensive methods to design and manufacture new products. Commercial printing technology uses software to design a three-dimensional computer-aided model. Printing technology is becoming increasingly accessible, reduces your production waste, and is more sustainable than traditional, fuel-consuming equipment. This has allowed many entrepreneurs like yourself increased flexibility over the design and production of their products. If you are looking for the top cost-effective strategies to manufacture new goods, consider 3D printing technology.

Build It Yourself (DIY)

When it comes to designing your products, there is no cheaper method than doing it yourself. If your product concept is relatively easy to design and assemble, consider attempting to build it yourself. Make a list of all the supplies you need to build your product. Check with your local hardware store to see what type of equipment they carry. Not only does self-assembly save you money, it better familiarizes you with the functions of your designed product. When you build products yourself, you can utilize savings to test market new products. If you have previous knowledge and expertise in how your product should work, consider purchasing the equipment to build it yourself.

Conclusion

Entrepreneurs are constantly looking for the best cost-effective methods to build their planned product designs. The first step is to consider the traditional manufacturing methods. Assess opportunities foam injection molding your product prototype. Consider custom production options with local businesses and experts in your area. If you have access to the technology, consider 3D printing your product designs. Furthermore, in order to save additional money throughout your manufacturing process, consider building it yourself. Consider the points above if you are interested in the top cost-effective ways to design new products.